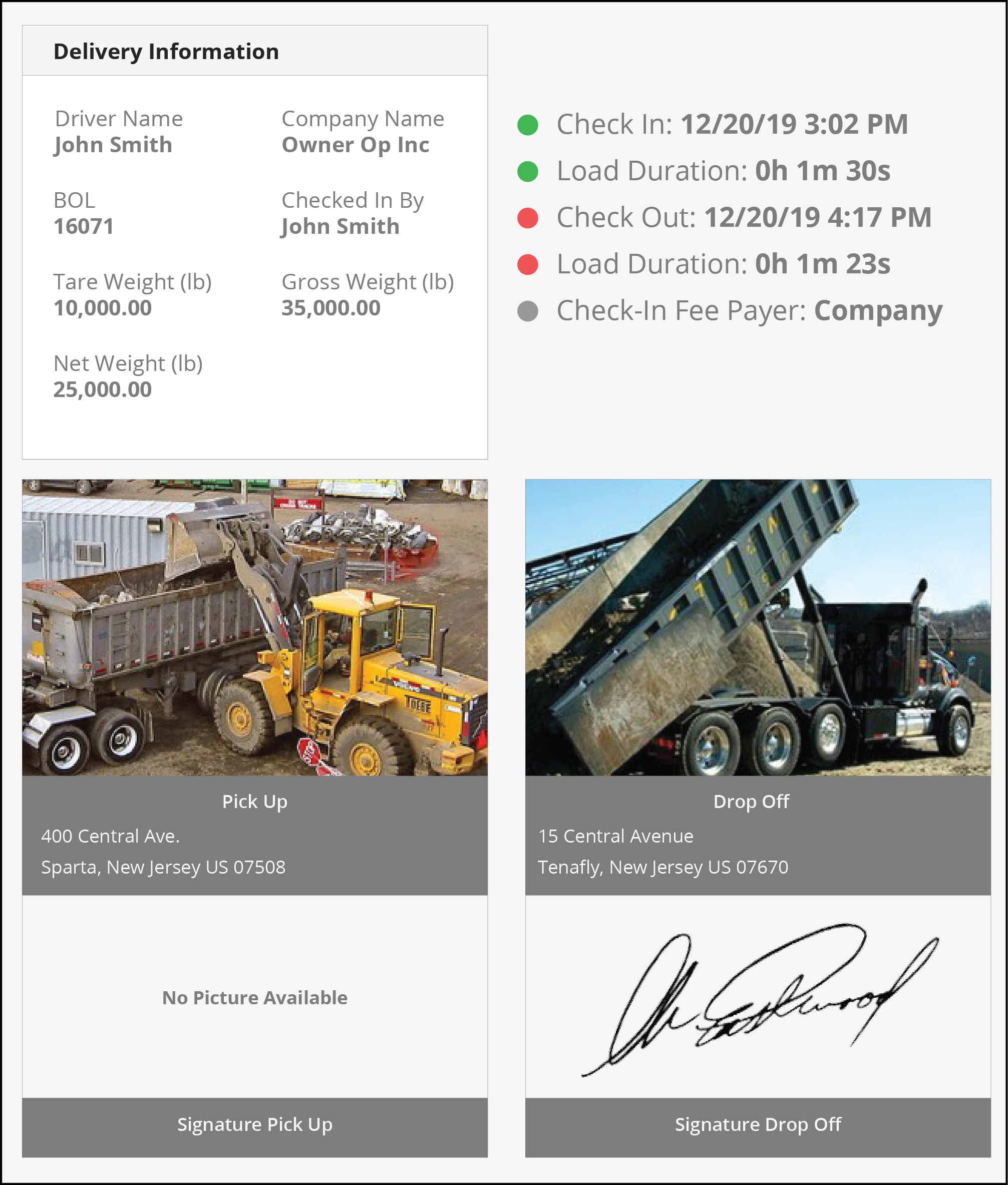

Eliminate Paper Tickets From Your Aggregates Yard

GO GREEN

Integrate your drivers, and your aggregates facilities into

your network and use

TruckPay to eliminate the paper work.

-

No more lost tickets.

-

No more illegitimate tickets.

-

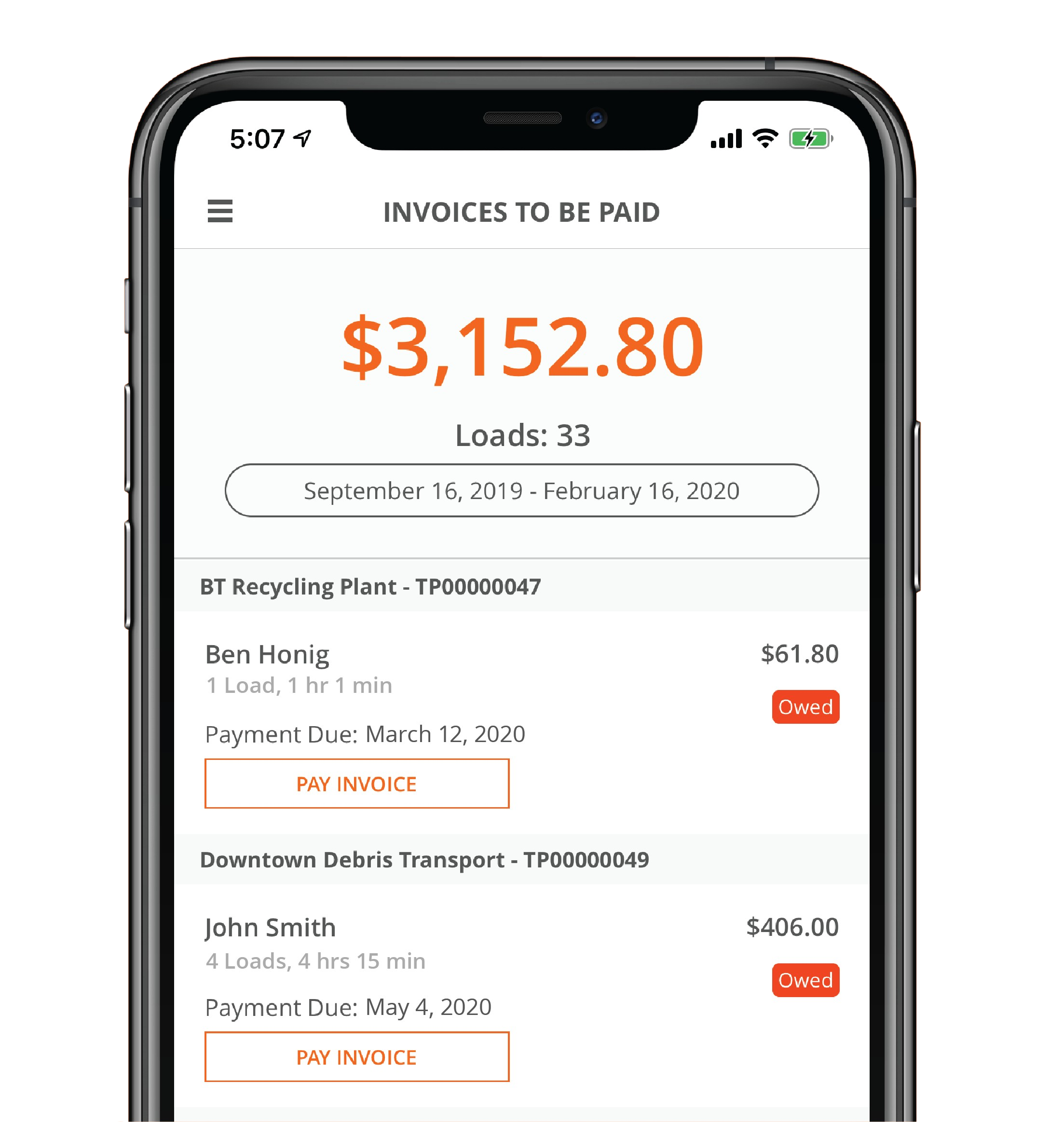

No more wasted time counting, sorting or validating tickets.

-

No need to photo scan tickets

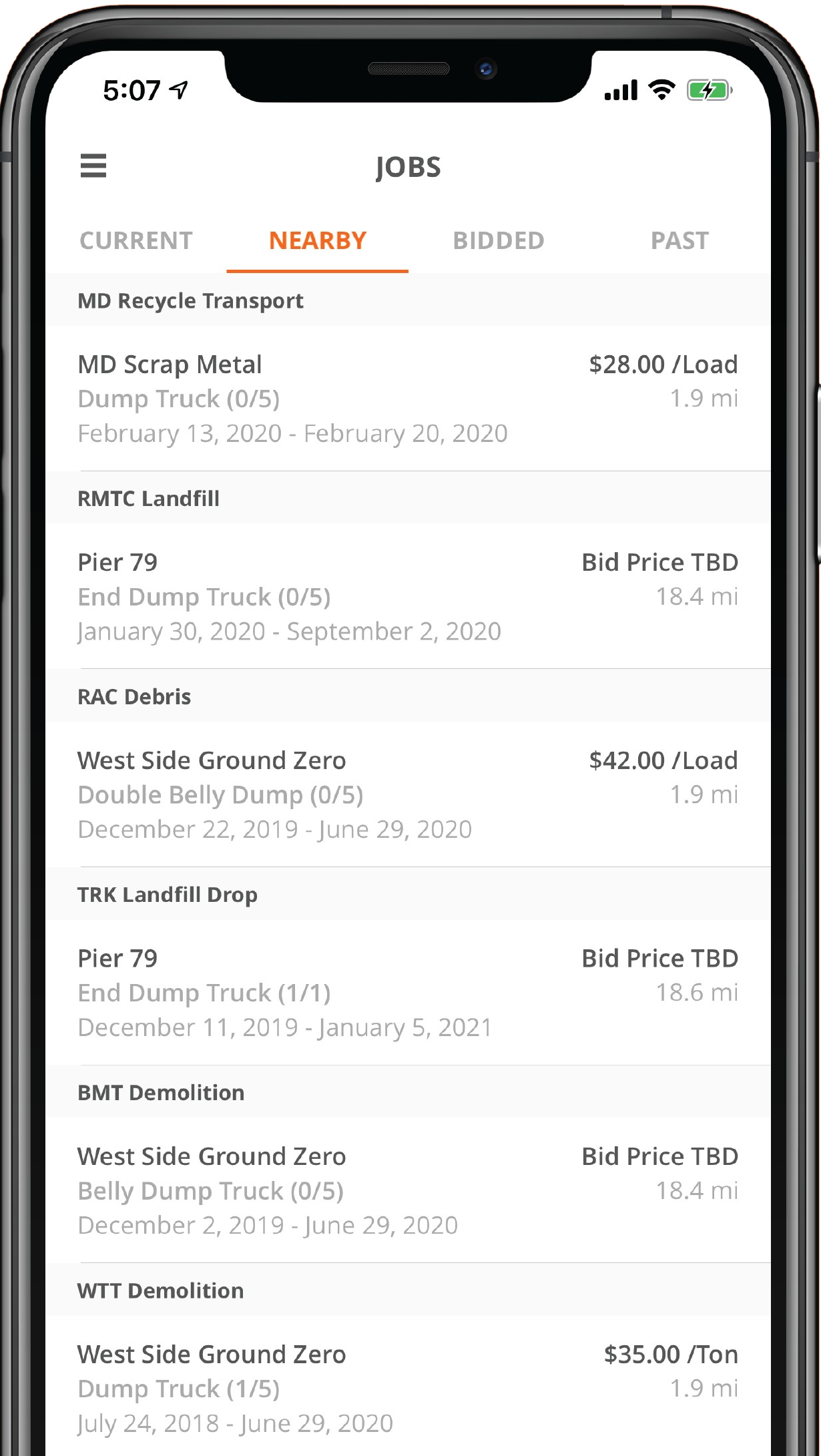

LEVERAGE METRICS FROM REAL TIME MATERIAL TRACKING OF ALL AGGREGATE DELIVERIES.

-

How long does it take to load and unload trucks?

-

Which carriers are moving the most/least aggregates to which customers?